Steam is an essential element of the coffee machine. It is crucial for making drinks that contain milk (lattes, cappuccinos, emulsions).

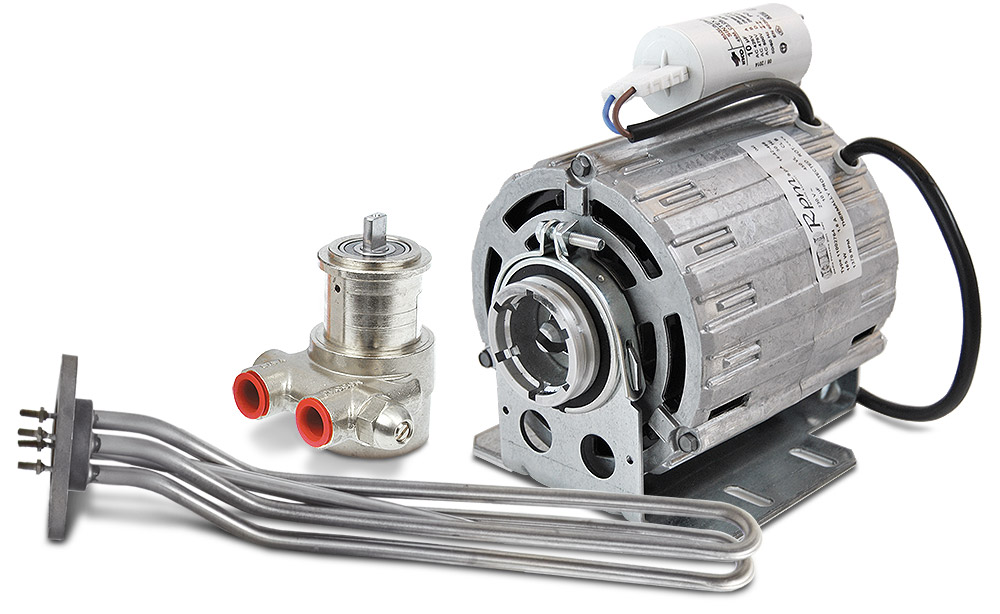

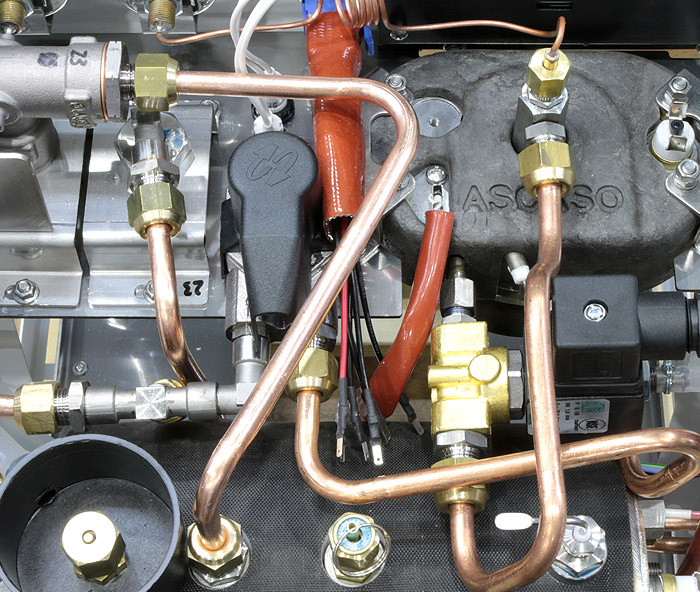

In response to baristas’ needs, we have developed a system with a large capacity as well as the flexibility to allow maximum control during use.- Excellent steam power thanks to a specific, large capacity boiler.

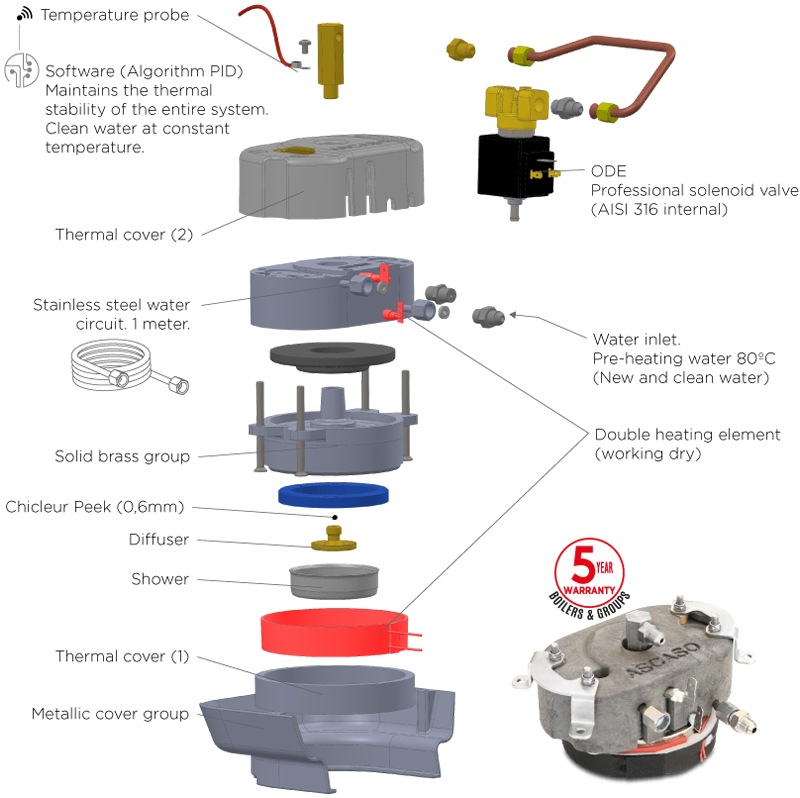

- PID Temperature Control

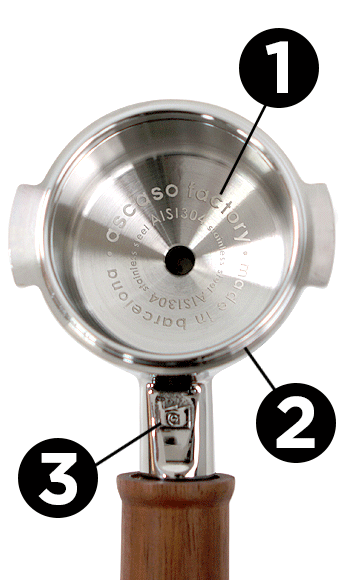

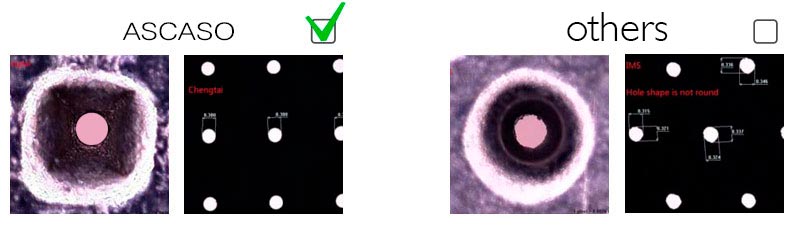

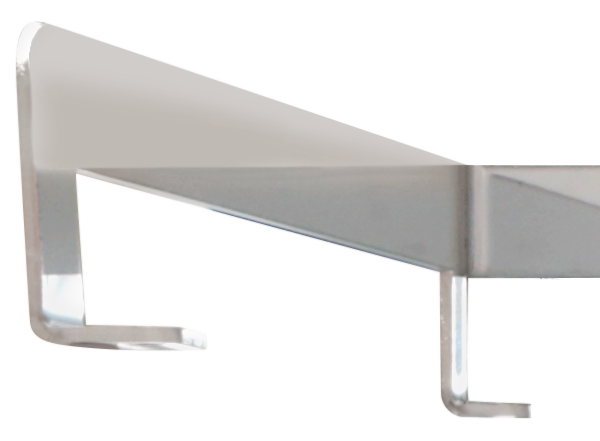

- Exclusive in-house technology steam nozzle in stainless steel with two positions.

- Very long, multi-directional steam wand with thermal protection.

- Ergonomic lever design.

- Steam tips with a special angle and design.

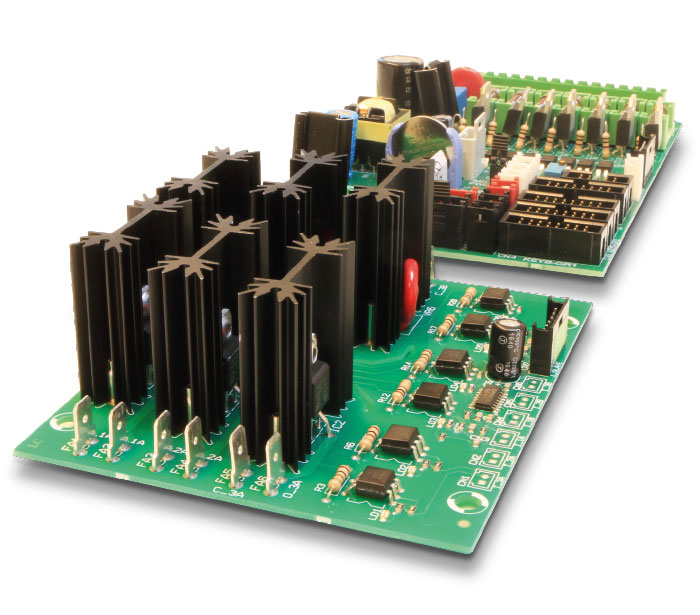

Easy and optimal temperature regulation lets you select the appropriate extraction process for each coffee, producing excellent results.

Easy and optimal temperature regulation lets you select the appropriate extraction process for each coffee, producing excellent results.