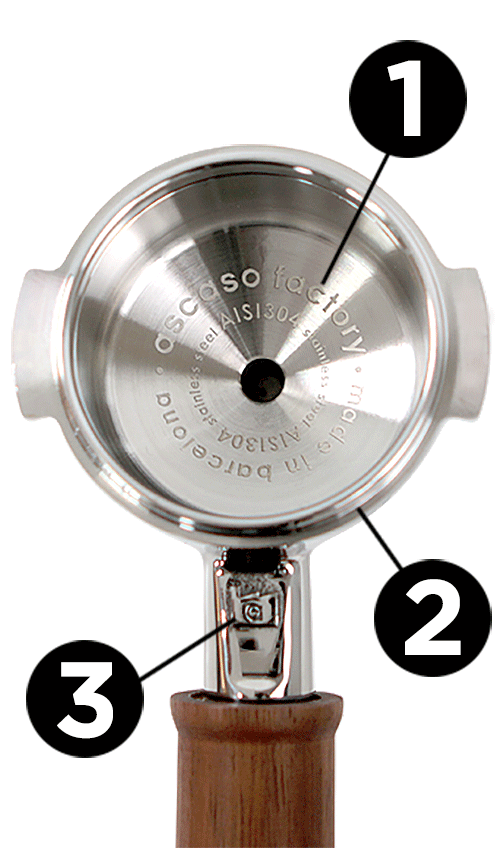

Ø58mm Stainless steel filter and portafilter

We only use the Stainless Steel Portafilter (including the 1 and 2 coffee spouts). In the entire Home Pro (Dream One / Pid, Steel) and Professional (Bar, Baby T, Barista T, Big Dream T) range.

We stopped using brass and chrome on this key component. The advantages are multiple:

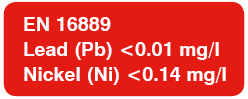

-Health. Stainless steel is the food material par excellence. Even with the use of low lead brass, there are metal migrations in the beverage. We also remove the chrome, which ends up in the cup. The traditional chrome-plated brass filter holder is black on the inside in a few weeks, while the stainless steel one is unalterable over time.

Quality of material. Stainless steel is a much harder material than brass. Its lifespan is much longer.

-Cleaning. Much easier to clean and more resistant.

-Esthetic. We have provided this filter holder with several details that give the product a better image:

- Internal laser marking

- Glossy finish

- Logo on the handle

Silicone seal ring

Material: Silicone. Can withstand temperatures of up to 100º. Our tests show that they have double the normal lifespan of standard high-quality rubber seal rings. Food safe material. In green. Odorless and tasteless.

Design: Specially designed rubber seal rings. Thick and flexible. The silicone makes engaging the portafilter easier thus less effort and strain on your wrists.

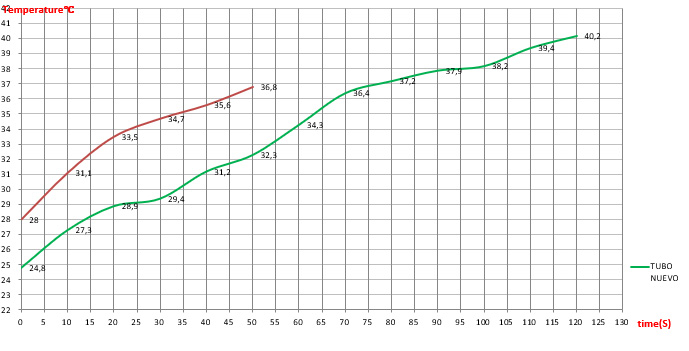

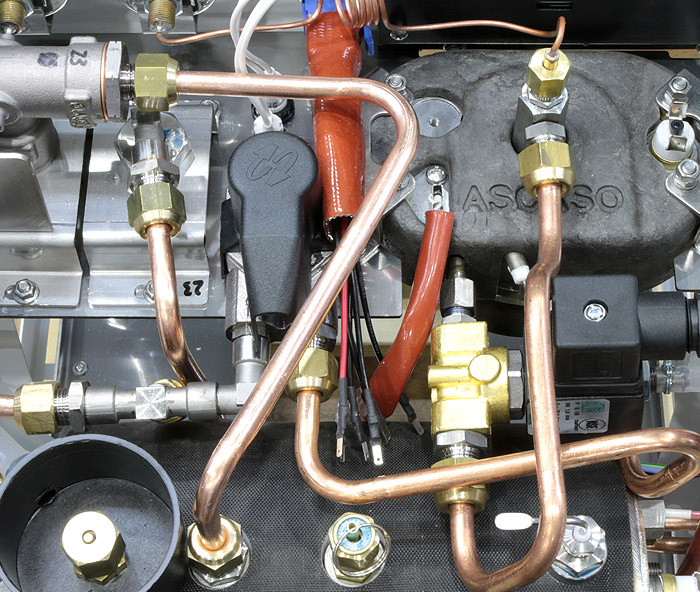

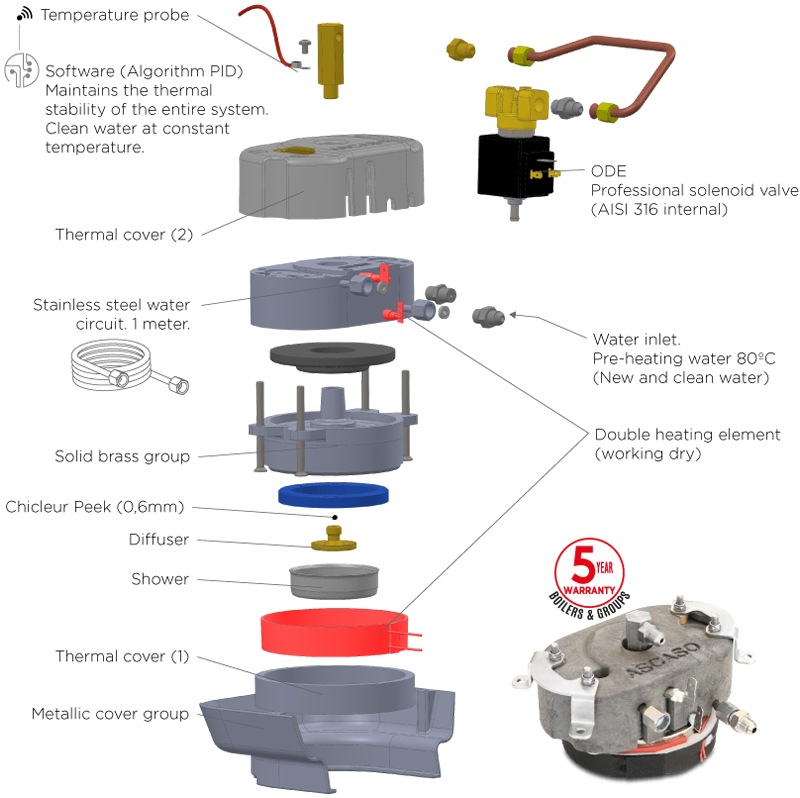

Easy and optimal temperature regulation lets you select the appropriate extraction process for each coffee, producing excellent results.

Easy and optimal temperature regulation lets you select the appropriate extraction process for each coffee, producing excellent results.