My Store

DUO STEEL PID - MATT WHITE - ASCASO

DUO STEEL PID - MATT WHITE - ASCASO

Couldn't load pickup availability

- Clean water. Here it is constantly renewed and clean for every coffee. The taste and smell of the coffee are unaffected. As the water does not stand in the boiler, being constantly re-heated, quality is not affected.

- Thermal stability. Quality in cup. Thanks to its high capacity and internal pipe measuring over a metre long. Optimised with electronic temperature control.

- 100% food-safe. AISI 316 stainless steel water circuit. No metal migration in water.

- Less limescale build-up. Easy-to-clean stainless steel circuit reduces limescale build-up.

-

Steam. Unlimited steam supply. Constant pressure. No damage to the heating element caused by low water levels. Reliability and quality.

(versatile)

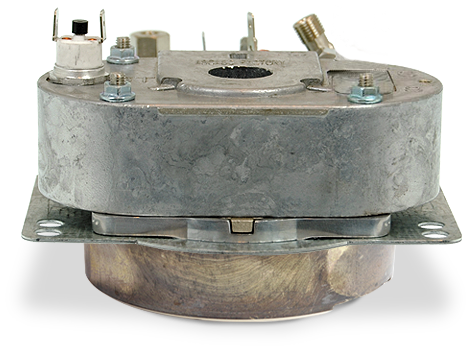

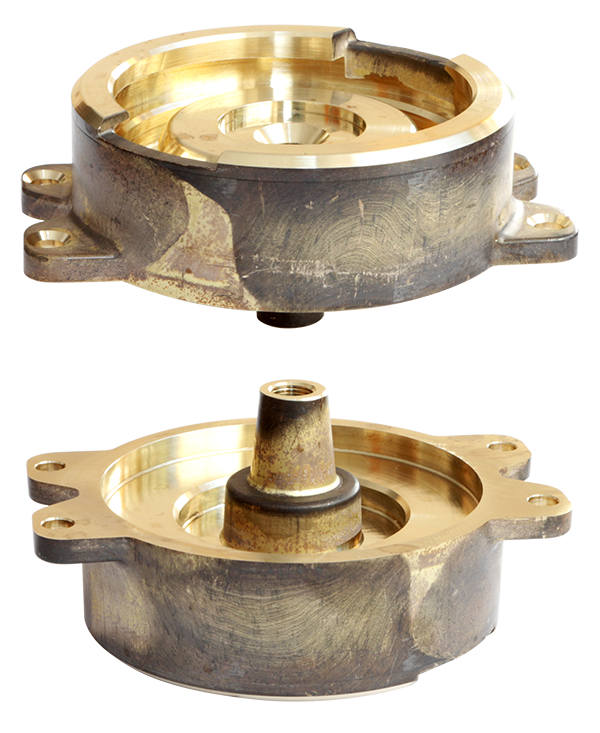

Coffee group is manufactured lead free brass.

New software: Instant, constant and powerful.

- More steam power is gained by increasing the working surface of the steam circuit.

- Extra steam pressure can be generated just by delaying the opening of the tap after activating the system.

- Our new software algorithm has increased the power of steam in 25%!!

-

Improves energy consumption. We reduce it from 35% to 70%, according to EN60661 test.

-

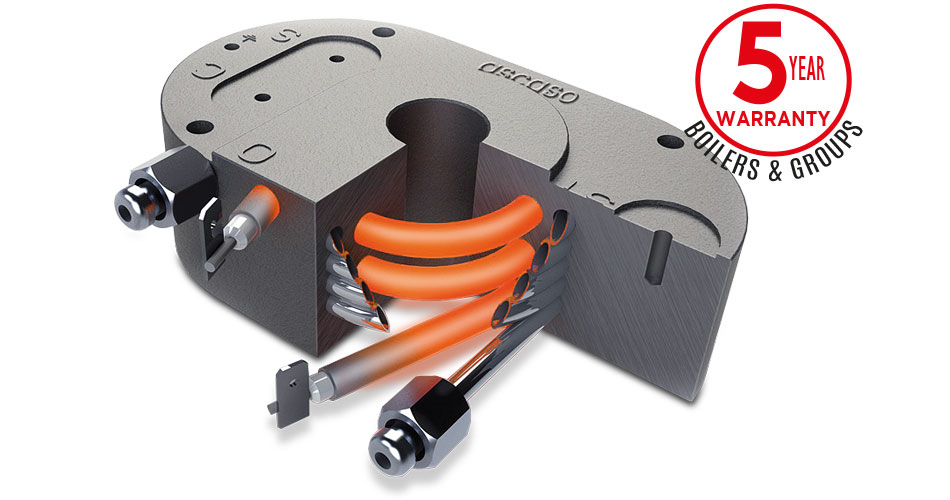

We avoid heating element failures. Ascaso also offers a 5-year warranty on the steam unit that includes it.

Vacuum valves, safety valves and immersion probes are also eliminated.

-

Waiting time for activation 2 minutes. Our steam unit is ready within 2 minutes after switching on. Once switched on, steam generation is instantaneous. A boiler takes between 15 and 25 minutes from start-up.

-

Instantaneous regeneration time. Constant steam. A boiler takes several minutes to recover if it has previously made steam, proportionally to its use. With our system the waiting time is zero. Throughout the process it does not lose steam, it is constant for 3 minutes (maximum established for system safety) and then recovers instantly.

- We use clean water in every steam service (no water constantly overheated).

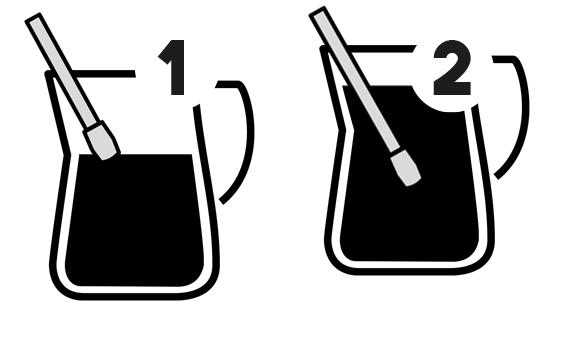

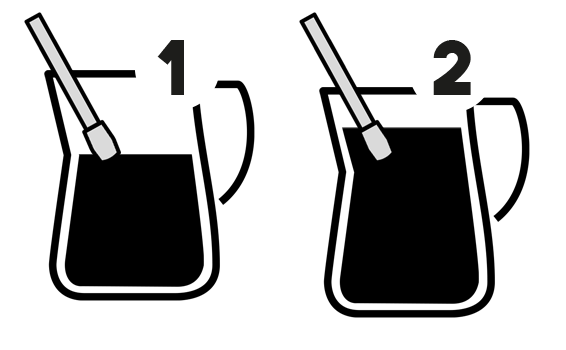

To get a professional result as in a boiler system, we have to change only a little the way of frothing: Work from the beginning to the end on the surface.

In a boiler system, we are used to working on the surface to provide air and then in depth to create circulation and heat the milk.

In a boiler system, we are used to working on the surface to provide air and then in depth to create circulation and heat the milk.

With our system we achieve the same result by working only on the surface: first to bring in air and then lower it just a little to create circulation and heat. The process is a little slower than with a boiler.

With our system we achieve the same result by working only on the surface: first to bring in air and then lower it just a little to create circulation and heat. The process is a little slower than with a boiler.

Watch this video where we frothing milk in the DUO with the two standard nozzles:

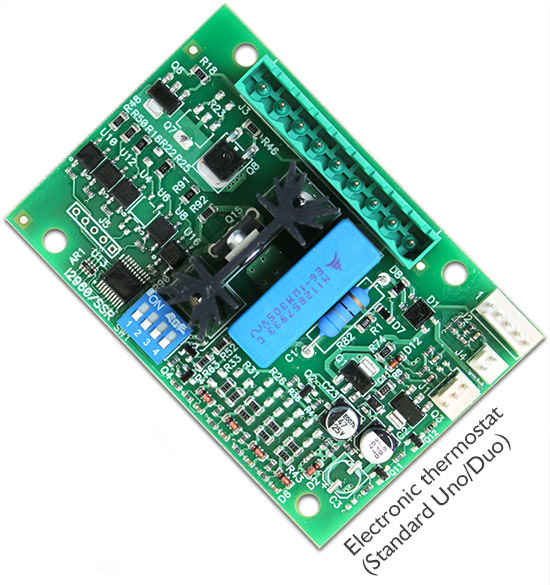

The electromechanical pressure switch is eliminated. Common in the industry, but not very precise and with mechanical failures.

Selection of the temperature of the coffee group by means of the display. From 110ºC to 165ºC

We incorporate a steam knob in place of the switch.

- You don't have to wait a second to get steam. Simply activating the steam function allows us to open or close the tap to get steam instantly.

- More professional approach to steam generation operation.

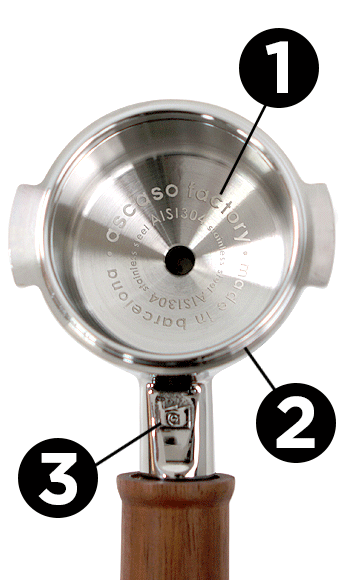

Thanks to its ergonomic design, it has a strong yet pleasant feel. Non-slip grip. It is tilted 10º for ease of use, while the horizontal placement of the filter holder in the delivery group ensures perfectly pressed coffee grounds.

We only use the Stainless Steel Portafilter (including the 1 and 2 coffee spouts). In the entire Home Pro (Dream One / Pid, Steel) and Professional (Bar, Baby T, Barista T, Big Dream) range.

We stopped using brass and chrome on this key component. The advantages are multiple:

-Health. Stainless steel is the food material par excellence. Even with the use of low lead brass, there are metal migrations in the beverage. We also remove the chrome, which ends up in the cup. The traditional chrome-plated brass filter holder is black on the inside in a few weeks, while the stainless steel one is unalterable over time.

Quality of material. Stainless steel is a much harder material than brass. Its lifespan is much longer.

-Cleaning. Much easier to clean and more resistant.

-Esthetic. We have provided this filter holder with several details that give the product a better image:

- Internal laser marking

- Glossy finish

- Logo on the handle

6 professional filters standard (2 traditional, 2 pressurized, 1 blind and 1 monodose E.S.E.)

Laser engraving, including a different serial number for each filter.

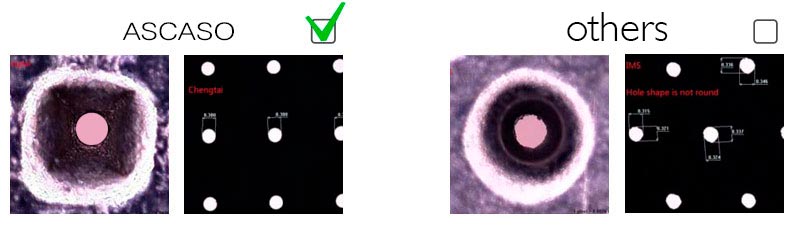

Our cutting-edge production process guarantees optimum results time after time. Filter by filter. Hole by hole. If not, there will be significant differences in the cup and system changes (over-/under-dispensing).

The circular perforations are totally uniform and always the same size (maximum tolerance of 0.02 mm difference between one hole and the next).

Its design (a geometric pyramid for the holes and a 94º angle) guarantees uniform dispensing and reduces possible sediment in the coffee and the blocking of the holes.

Available in 4 sizes (18gr and 21gr are optional)

Externally adjustable pressure valve.

TFM (high performance) gasket closure system.

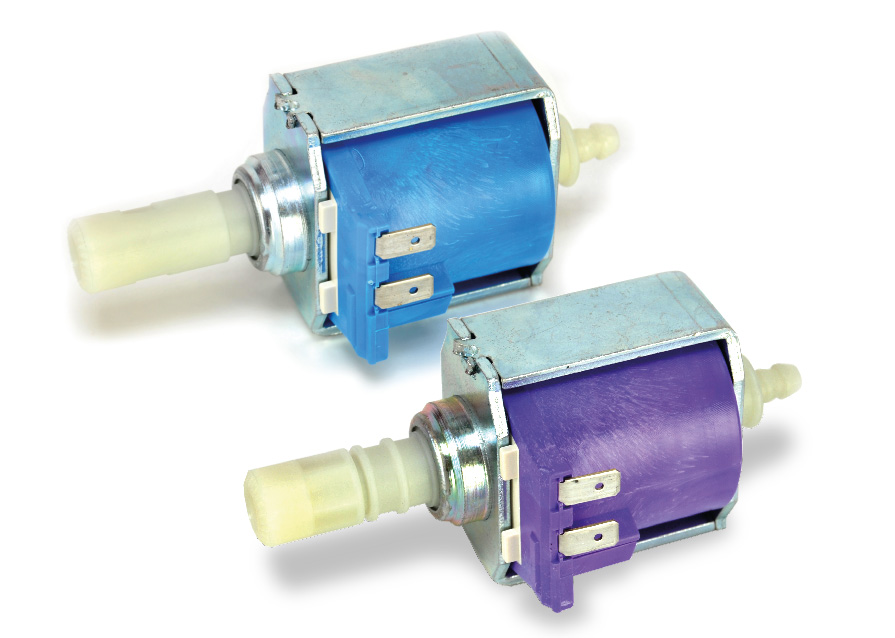

Cutting-edge electronic components. 'Tropicalized' chipset. Intelligent steam management in the thermoblock.

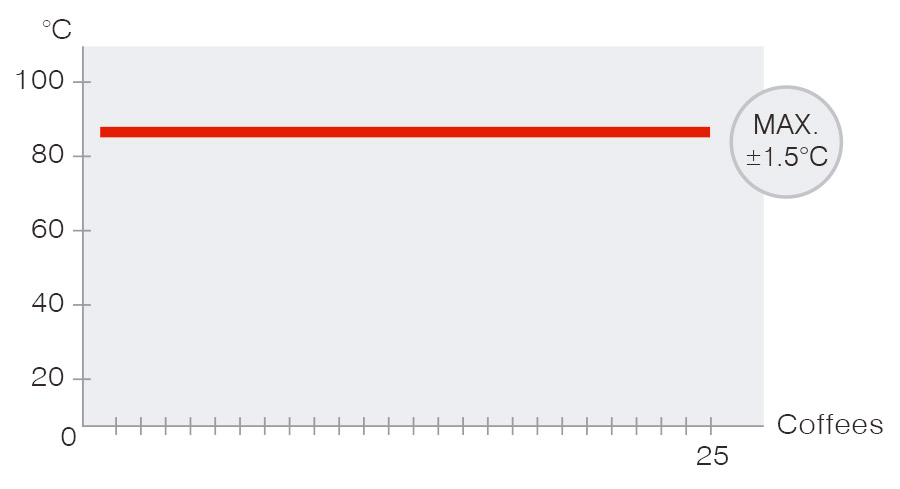

Fully independent electronic temperature control for each group, (up to 8 possible options ranging from 90°C to 106°C). We guarantee a maximum deviation of +/-1.5°C. In continuous or intermittent use. From the first coffee to the very last.

The traditional boiler and bimetal thermostats offered a deviation value of up to +/-5°C.

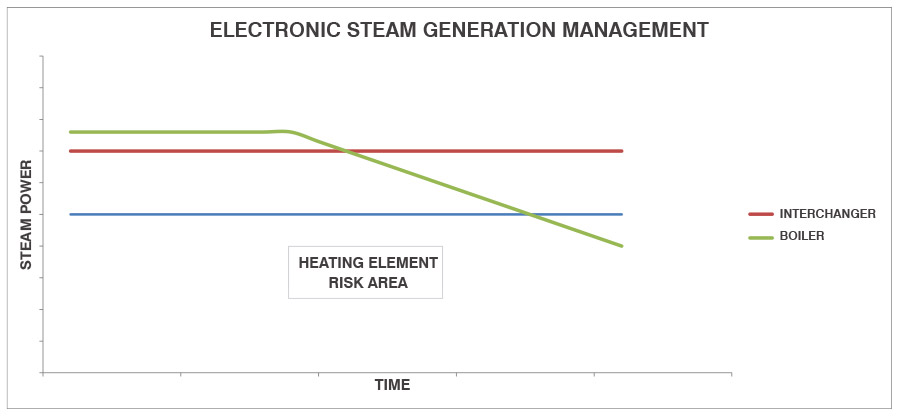

Much more stable and professional steam management

With electronic management, the amount of water entering the group is based on the machine’s temperature (not on the amount of water inside, as in the case of the boiler), by changing the pump activation frequency, thereby always producing dry steam.

The steam pressure in the first 10 seconds is superior with the boiler system but, as no water is added, that pressure runs out over time. With Thermoblock, the pressure is continuous and unlimited.

The boiler system is much less reliable in terms of element durability. Lack of water causes the system to ‘struggle’ when using steam services. Additionally, in the boiler system, use of a steam service requires the user to fill the boiler manually afterwards.